Sheet Metal Fabrication

Sheet metal fabrication is a cornerstone of modern manufacturing and construction, offering precise, cost-effective solutions for everything from HVAC systems to architectural features. At New York Metal Fabricator, we provide expert sheet metal services for residential, commercial, and industrial clients across New York City. Whether you're building custom ductwork, signage, enclosures, or panels, our team delivers accuracy, speed, and quality with every cut and bend.

What Is Sheet Metal Fabrication?

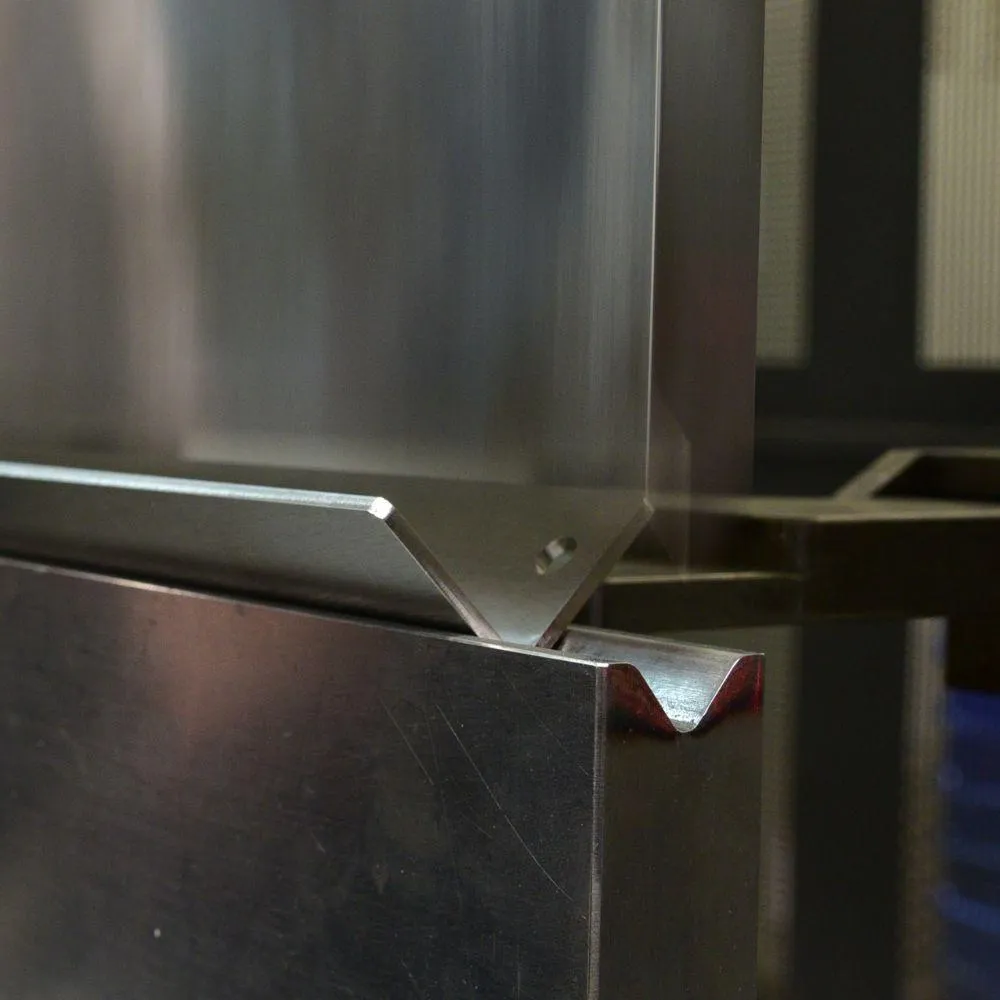

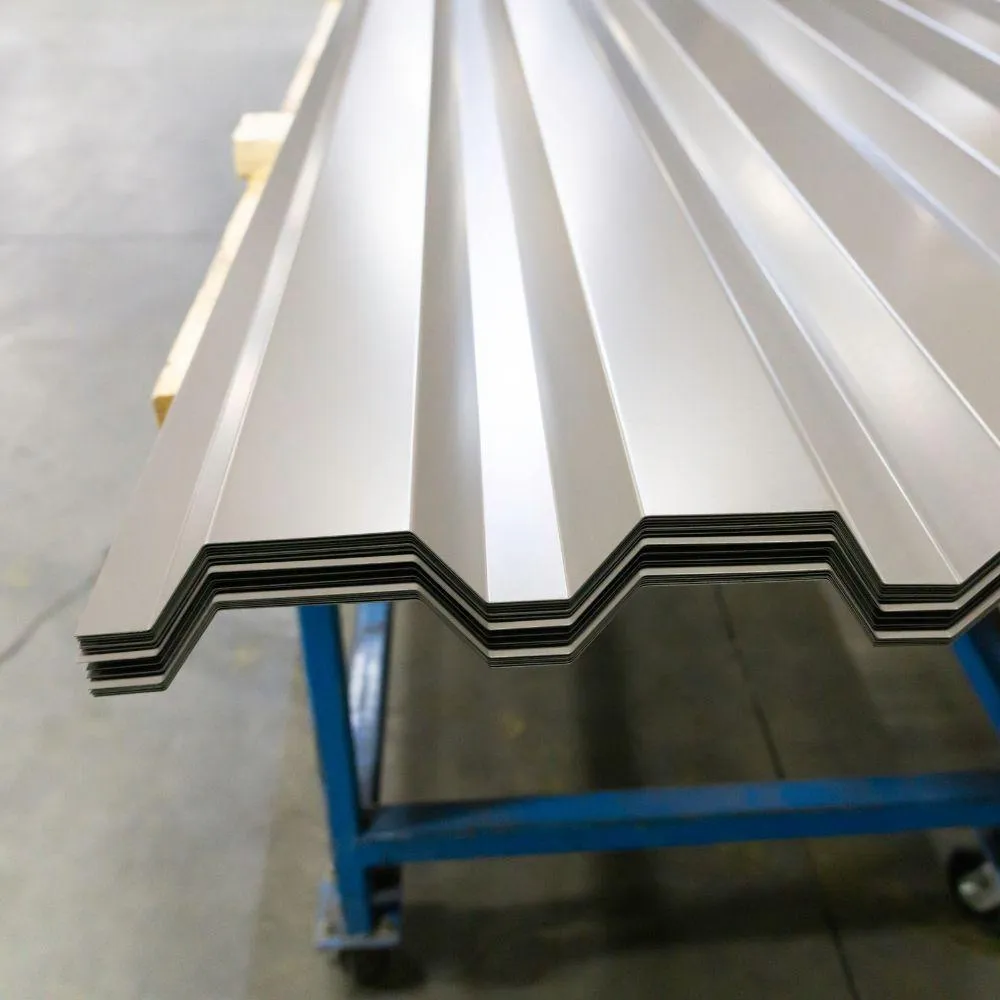

Sheet metal fabrication involves cutting, bending, and assembling flat sheets of metal into usable parts and structures. It is used in a wide range of industries, including construction, mechanical systems, electronics, and interior design. The advantage of sheet metal lies in its flexibility — it can be shaped into complex forms while remaining lightweight and strong. Depending on the project, we may work with aluminum, galvanized steel, stainless steel, or copper. Fabrication techniques include shearing, laser cutting, punching, press braking, and rolling. With the right design and process, sheet metal can achieve tight tolerances, clean finishes, and long-lasting performance even in demanding conditions.

Common Applications of Sheet Metal in NYC Projects

In a city as dense and diverse as New York, sheet metal plays a role in everything from infrastructure to interiors. One common use is in HVAC duct systems, where lightweight, corrosion-resistant sheet metal is formed into ventilation paths for commercial and residential buildings. It’s also used for roofing flashings, electrical enclosures, signage, access panels, and decorative cladding. Architects rely on sheet metal to create unique finishes and textures for both indoor and outdoor surfaces. Because it’s relatively thin, sheet metal is also easy to install in tight or awkward spaces — a key advantage in urban renovations or retrofits. Its adaptability makes it a practical solution across multiple industries.

What’s Included in Our Sheet Metal Fabrication Services

Our sheet metal fabrication process begins with design consultation, where we review your application, specifications, and performance requirements. If you already have technical drawings, we’ll work directly from them; if not, we can assist with drafting or refining the design using CAD software. Once the design is finalized, we select the appropriate material and thickness for your project, considering factors such as weight, weather resistance, and appearance. The fabrication process may involve cutting (laser, plasma, or shear), bending (press brake), punching, and forming, depending on the complexity of the piece. We perform thorough quality control checks to ensure accuracy and clean edges, and we can also add finishing services like powder coating, galvanizing, or polishing. For multi-part projects, we offer assembly and can coordinate delivery or installation as needed. From a single custom panel to large production runs, our sheet metal services are built around precision, durability, and efficiency.

© Copyright 2025 New York Metal Fabricator. All Rights Reserved.